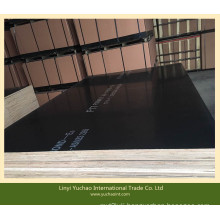

Film Faced Plywood or Construction Plywood

Basic Info

Model No.: PIN097

Product Description

Model NO.: PIN097 Grain: Iregular Grain Bonding Strength: Ⅲ(Nc) Formaldehyde Emission Standards: E2 Place of Origins: China Usage: Outdoor Core: Poplar,Hardwood,Eucalyptus,Birch, Tolerance: +/-0.5mm F&B: Black Film,Brown Film Moisture: Less Than 14% Application: Used for Construction Building,Building Formwork E Specification: CARB P2, CE, J A S HS Code: 4412 Material: Hardwood Core Core Polywood: Callular Board plywood Type: 13-Ply Specifications: 1220*2440*18mm Grade: Grade One Size: 1220X2440mm,610X2440mm,915X1830mm,1250X2500mm Thickness: 9,12,15,16,17,18,20,21,25,27,30mm Glue: Mr,WBP,Phenic WBP Finish: Smooth,Mesh(Anti-Slip),with or Without Logo Density: 600~580kgs/Cbm Trademark: PIONERO Origin: Linyi China

Film faced plywood,shuttering panel formwork board Specification :

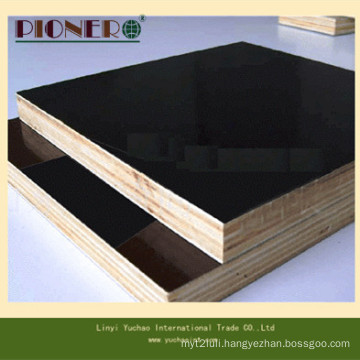

1)Thickness: 9mm ,12mm,15mm,18mm,21mm,24mm.

2)Size: 915x1830mm,1220x2440mm,610X2440MM,1200x2400mm,1250x2500mm, 610x2440x18mm for Middle East Market.

3)Core: Poplar core,Hardwood core,Birch core,Combi core,renewed core etc.

4)Film: black film 240g/sqm, brown film 120g/sqm, yellow film plywood, green film plywood, red film plywood etc.

Wiremeshed anti-sliperry plywood, W/F plywood, one side smooth another side wiremeshed anti-slip.

5)Glue: Phenolic WBP glue; Melamine WBP glue; MR glue

6)Edges Treatment : firslty sealed by phenolic waterproof glue, then painted by water-proof paint in black color or brown color or as requested

Packing: covered by plastic bag, fastened by steel belts with pallets, strong export packing.

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use Film Faced Plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time.

Contact us if you need more details on Black Film faced Plywood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Film Faced Plywood、Shuttering Plywood. If these products fail to match your need, please contact us and we would like to provide relevant information.

Film faced plywood,shuttering panel formwork board Specification :

1)Thickness: 9mm ,12mm,15mm,18mm,21mm,24mm.

2)Size: 915x1830mm,1220x2440mm,610X2440MM,1200x2400mm,1250x2500mm, 610x2440x18mm for Middle East Market.

3)Core: Poplar core,Hardwood core,Birch core,Combi core,renewed core etc.

4)Film: black film 240g/sqm, brown film 120g/sqm, yellow film plywood, green film plywood, red film plywood etc.

Wiremeshed anti-sliperry plywood, W/F plywood, one side smooth another side wiremeshed anti-slip.

5)Glue: Phenolic WBP glue; Melamine WBP glue; MR glue

6)Edges Treatment : firslty sealed by phenolic waterproof glue, then painted by water-proof paint in black color or brown color or as requested

Packing: covered by plastic bag, fastened by steel belts with pallets, strong export packing.

| Product Name | Film Faced Plywood/Shuttering Plywood/Construction Plywood/Concrete Plywood | ||||

| Size | 1220x2440mm, 1250x2500mm, 915x1830mm or as clients requirement | ||||

| Thickness | 9~21mm | ||||

| Thickness Tolerance | +/-0.3~0.5mm | ||||

| Face/Back | National film (black or brown), imported dynea brown film or anti-slip film (black or brown) | ||||

| Film Gram | 240g/m2 (black film), 120g/m2 (brown film) | ||||

| Core | Poplar, hardwood, eucalyptus, birch, pine, combi, ect. | ||||

| Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | ||||

| Edge Treatment | Sealed by waterproof paint | ||||

| Glue | MR, Melamine or WBP | ||||

| Grade | A grade or as clients requirement | ||||

| Density | 500~680kg/m3 | ||||

| Technical Parameters | Moisture Content | 10%~15% | |||

| Water Absorption | ≤10% | ||||

| Modulus of Elasticity | ≥5000Mpa | ||||

| Static Bending Strength | ≥30Mpa | ||||

| Surface Bonding Strength | ≥1.60Mpa | ||||

| Internal Bonding Strength | ≥0.90Mpa | ||||

| Screw Holding Ability | Face | ≥1900N | |||

| Edge | ≥1200N | ||||

| Usage & Performance | Film faced plywood is widely used for construction concrete formwork. It has many advantages compared with iron formwork. The advantages are as below: 1. The biggest size of the film faced plywood is 1250x2500mm, which could decrease the number of the joints and increase the working efficiency. 2. Light weight, It's more suitable for high-rise building and bridge construction. 3. It can be used for many times if used and stocked correctly, which can save the cost greatly. 4. It can keep the surface smooth and beautiful when used for pouring, and you don't need to plaster the wall for second time, as it can decorate directly that can decrease the construction period 30%. 5. It will not pollute the surface of the concrete, but iron formwork has the disadvantages of rusty and erosive, ect. 6. It is good for construction in winter that it can be used as template for curved surface. 7. It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling. It can be processed to template with all shapes according to needs. | ||||

| Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | ||

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | ||||

| Loading Quantity | 20'GP | 8pallets/22cbm | |||

| 40'GP | 16pallets/42cbm | ||||

| 40'HQ | 18pallets/53cbm | ||||

| MOQ | 1x20'FCL | ||||

| Supply Ability | 5000cbm/month | ||||

| Payment Terms | T/T or L/C at sight | ||||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||||

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use Film Faced Plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time.

Contact us if you need more details on Black Film faced Plywood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Film Faced Plywood、Shuttering Plywood. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Film faced Plywood

Premium Related Products

Other Products

Hot Products

HPL faced plywood formica HPL plywood for furnitureHight glossyUV MDF for kitchen cabinet1220x2440x2.0mm/2.3mm/2.5mm and 3.2mm dark brown hardboardVeneer Sandwich Plywood For wall panel with cheap pricedouble sided melamine laminated plywood melamine faced plywood for cabinetsinterior wall paneling decorative waterproof hardboard panels4*8 white melamine laminated particle board for furnitureNatural Chinese Ash Face Veneer for Plywoodslotted mdf wall board decorative wall board with aluminum bar16mm waterproof chipboard to make kitchen cabinetsfilm faced plywood for building and constructionmelamine Laminated blockboard, 4*8 poplar Block boardlow price marine plywood construction plywoodHollow core chipboard sheet / tubular chipboard for door core use12mm 15mm melamine paper faced MDF boardJSXD2878/JSXD2879 HPL/Formica sheet/Compact laminate/Decorative laminate sheet