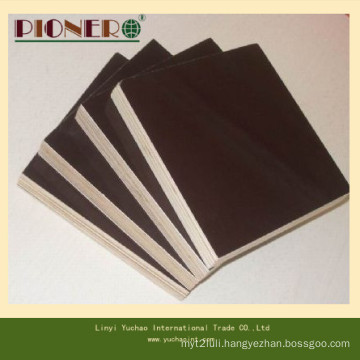

Linyi Best Price Film Faced Plywood for India

Basic Info

Model No.: PIN098

Product Description

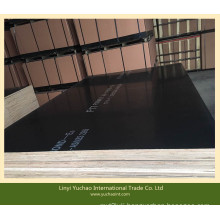

Model NO.: PIN098 Grain: Iregular Grain Bonding Strength: Ⅲ(Nc) Formaldehyde Emission Standards: Mr Place of Origins: China Usage: Indoor, Outdoor Face/Back: Brown/Black, Red, Yellow Film Tolerance: +/-0.2mm to 0.3mm Glue: E0,E1,E2,Mr Certificate: ISO9001,American Carb,Ce Packages: Cover with plywood or Corrugated Paper Specification: CARB P2, CE, J A S HS Code: 44123900 Material: Poplar Core Polywood: Callular Board Plywood Type: 13-Ply Specifications: 1220*2440*15mm Grade: Grade One Size: 1220*2440/1250*2500mm and Customized Thickness: 2mm to 30mm and Customized Core: Poplar, Hardwood, Hardwood Combi Moisture: 10%-15% Usages: Construction,Furniture,Decoration,Packing. Trademark: PIONERO Origin: Linyi China The Film Faced Plywood:

Size: 1220*2440/1250*2500mm.

The thickness is from 9 -40MM.

Glue: MR, WBP and Melamine.

Film: Black film, brown film, Dynea film, yellow film etc.

Core: Poplar, birch, hardwood and other combined core.

1, Black film, poplar core

Glue: MR, WBP; Surface: Black film, 240g /m2; Core: Poplar; MC: 8-14%.

2, imported film

Thickness: 8 -40MM; Glue: WBP; Surface: Dynea film, 120g /m2; Core: Poplar, birch; MC: 8-14%.

Payment terms: T/T, LC at sight.

Price Terms: EXW, FOB, CNF, CIF.

Usages: Can be widely used in construction, mould, etc.

Packing: Standard export packing by plywood or MDF, wrapped in plastic bag and then strengthened by iron straps.

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use Film faced Plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time. Contact us if you need more details on Film Faced Plywood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Marine Plywood、Shuttering Plywood. If these products fail to match your need, please contact us and we would like to provide relevant information.

Size: 1220*2440/1250*2500mm.

The thickness is from 9 -40MM.

Glue: MR, WBP and Melamine.

Film: Black film, brown film, Dynea film, yellow film etc.

Core: Poplar, birch, hardwood and other combined core.

1, Black film, poplar core

Glue: MR, WBP; Surface: Black film, 240g /m2; Core: Poplar; MC: 8-14%.

2, imported film

Thickness: 8 -40MM; Glue: WBP; Surface: Dynea film, 120g /m2; Core: Poplar, birch; MC: 8-14%.

Payment terms: T/T, LC at sight.

Price Terms: EXW, FOB, CNF, CIF.

Usages: Can be widely used in construction, mould, etc.

Packing: Standard export packing by plywood or MDF, wrapped in plastic bag and then strengthened by iron straps.

| Size | 1220*2440/1250*2500mm and customized |

| Face/back | Poplar, Birch,Pine,Maple, Hardwood |

| Thickness | 2mm to 30mm and customized |

| Grade | BB/CC, CC/CC, CC/DD,DD/EE, etc |

| Glue | E0,E1,E2,MR |

| Moisture | 10%-15% |

| Certificate | ISO9001,American CARB,CE |

| Usage | construction,Furniture,decoration,packing |

| Payment | T/T, L/C at sight |

| Delivery time | 10-15 days after receiving downpayment or L/C |

Features

Transference to concrete is set up very easily. There is no need for any transference preparation.

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use Film faced Plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time. Contact us if you need more details on Film Faced Plywood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Marine Plywood、Shuttering Plywood. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Film faced Plywood

Premium Related Products

Other Products

Hot Products

HPL faced plywood formica HPL plywood for furnitureHight glossyUV MDF for kitchen cabinet1220x2440x2.0mm/2.3mm/2.5mm and 3.2mm dark brown hardboardVeneer Sandwich Plywood For wall panel with cheap pricedouble sided melamine laminated plywood melamine faced plywood for cabinetsinterior wall paneling decorative waterproof hardboard panels4*8 white melamine laminated particle board for furnitureNatural Chinese Ash Face Veneer for Plywoodslotted mdf wall board decorative wall board with aluminum bar16mm waterproof chipboard to make kitchen cabinetsfilm faced plywood for building and constructionmelamine Laminated blockboard, 4*8 poplar Block boardlow price marine plywood construction plywoodHollow core chipboard sheet / tubular chipboard for door core use12mm 15mm melamine paper faced MDF boardJSXD2878/JSXD2879 HPL/Formica sheet/Compact laminate/Decorative laminate sheet